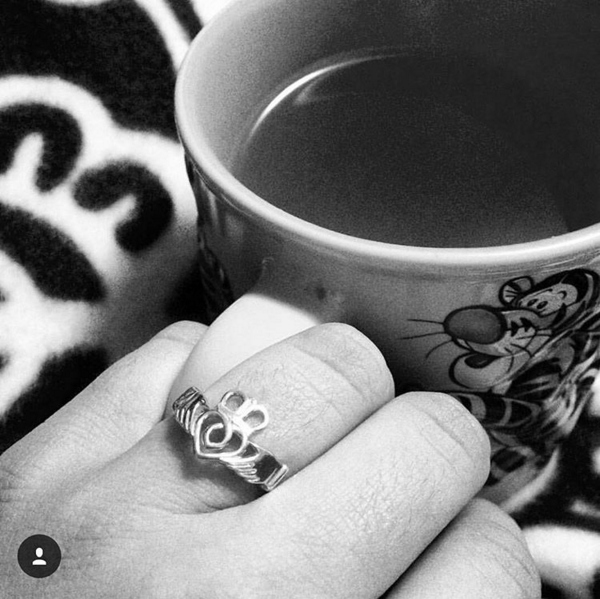

I had known about “rapid prototyping” for a while, which is what 3D printing was called for many years. My mind was blown though when I discovered Shapeways and saw how inexpensive 3D printing had become in 2012. Part of the reason I got into Celtic jewelry design is because I wanted to learn about 3D printing.

The hype around 3D printing was sky high as recently as a year ago. Amazing new products that could only be made with 3D printing were everywhere. Clothing designs made with 3D printing were in fashion shows. People were 3D printing food. 3D printing stocks were sky high. It seemed like the potential for this technology was limitless. Since then the stocks have tanked and enthusiasm has waned. What happened?

Nothing Happened

Nothing has really changed. The hype just got way ahead of the technology. 3D printing is still going to change the world eventually. It still may be many decades before all of us have a 3D printer in our house that we use to print products rather than buying them in a physical store or online retailer. Hobbyists and tinkerers will largely be the ones still buying them for personal use for a while.

This is normal for a new technology. Look at another technology that everyone was supposed to have in their home: personal computers. Computers existed in the 1960s. It wasn’t until the 1970s that the very first mass produced PC models were introduced. The only people using them at that time though were some businesses and hobbyists. I can remember way back to the 1980s when they started to spread a bit. Even then, this was still a fairly “early adoption” stage. It wasn’t until really the advent of the internet that really made them take off. The internet was the killer application that made everyone that didn’t already own one, want to buy one. The entire cycle took 30 to 40 years to run its course.

3D printing is basically in that early stage that PCs were in the 1970s or maybe early 1980s. It could easily be another 10 or 20 years before everyone decides that they want one. Like the PC, some product may come along that can only be made with a 3D printer that everyone might suddenly want. Time will tell.

This article talks about the “hype cycle” around new technologies like this. We are in the trough after the big peak on the graph. Ahead is slow and steady growth for many years to come.

The Impact on Manufacturing Will Be Enormous

In the meantime, 3D printing is going to make a bigger and more immediate impact in manufacturing. 3D printing has already been used for years by industry just to make mock-ups or prototypes of new products. 3D printers are finally reaching the stage where the quality is good enough to make products right out of the printer.

There are tons and tons of industries just drooling over 3D printing (or if they aren’t, they should be). The reason is because 3D printing is potentially the leanest of any manufacturing process to ever exist. If you can create a product with 3D printing then there is hardly any inventory. Everything can be made to order, and go from raw material directly to finished product in one step. This is just an example to illustrate what I’m talking about:

The process that 3D printing seems to be replacing fairly often is casting. Casting metals or plastics is a pretty efficient and inexpensive process today, but it has drawbacks. Casting only makes sense if you are going to produce big quantities of identical products, because you have to buy a mold. Molds can vary in price. In cases where molds are expensive, you need to buy large quantities to spread the cost of the mold over a large number of products. Then, because you just mass produced a large number of products, you have to carry all that inventory. Also in the flowchart I put a couple secondary operations. It is unusual for cast products to come directly out of the mold and not require some kind of secondary operation. And if you made 1,000 items in the casting step, now 1,000 items are waiting in the queue to go through the next step in the process.

3D printing is kind of the Holy Grail of lean manufacturing. It eliminates the need for a mold. So there is no need to buy a huge quantity of products to offset the cost of the mold. You can now make items one at a time, made to order. There is no more inventory to carry. The entire goal of lean manufacturing is to eliminate inventory at every step in the process. Inventory is money, and therefore waste. Today a lot of 3D printed products require secondary processes that I did not show. However, the need for secondary operations will be reduced as 3D printing quality improves. Also, since you are only making one piece at a time, at most there will be one piece waiting in the queue at that secondary operation, not 1,000.

Another thing that 3D printing provides is infinite customization. Instead of using a mold to make 1,000 identical products, you could use a 3D printer to make 1,000 unique products tailored specifically to each customer’s wants or needs. Here is one example. Athletic shoe behemoth Nike is looking at using 3D printing to make custom cushioning in their shoes:

Nike’s 3D Printing Ramp Up: Which Companies Will It Partner With?

Nike (NYSE:NKE) announced last week at its investor day that it’s turbocharging its 3D-printing efforts. The athletic shoe and apparel behemoth has been increasingly embracing the innovative technology for prototyping. However, several comments from top management suggest that the company intends to use 3D printing for general manufacturing of new cushioning systems, and for the production of custom cushioning systems tailored to an individual’s needs.

Large-scale manufacturing is surely a ways off, but the customized cushions could be a nearer-term goal. Said Chief Operating Officer Eric Sprunk: “Very recently, we’ve made a series of design and manufacturing discoveries with 3D printing that we believe will allow us to deliver a completely new, personal, performance cushioning system.”

Warehouses Will Shrink And Possibly Become Obsolete

When 3D printing becomes better at making final products, then the need for storing huge amounts of products in warehouses will diminish. Imagine Amazon in the distant future. Instead of needing to have enormous warehouses full of products with elaborate storage and retrieval systems, they could in theory just have several 3D printers that make products to order. Perhaps they would need to store the raw materials required for the 3D printing process, but this is much, much simpler (and far cheaper) than storing thousands and thousands of finished products.

The other application that could be impacted greatly is the service parts industry for cars, tractors, and other equipment. Let’s just look at cars. Right now, automotive companies have to store service parts in a warehouse. They could sit there for years, just waiting for someone that needs one to order one. This is very expensive. For a new part, they don’t know exactly how many are going to sell, so they have to make an educated guess at how many to stock. They also have to decide how many years they are going to store them. If you happen to own an older car, you may have a really hard time finding certain parts, because they only decided to store the parts for 10 years after the model went out of production, for example.

If you could use a 3D printer to make service parts to order, all these problems are eliminated. No need to guess how many parts to store because they will all be made to order. No need to decide how many years to store the parts for, because the file will reside on a hard drive, ready to be made by a 3D printer at any time, even decades from now. If you own an old car then you would not have a problem obtaining the parts you need. Jay Leno owns a 3D printer that he uses to make parts for his antique car collection. There’s no reason this idea couldn’t be replicated on a larger scale.

People who are bearish on 3D printing stocks may want to re-think their position (full disclosure: I own a few shares of 3D Systems Stock and Stratasys stock). Even if every house doesn’t own a 3D printer someday, they will still be widely used by industry. The most important research going on right now isn’t necessarily in making 3D printers faster and better (although that effort will never really end). The important research is in materials technology, and coming up with new materials that 3D printers can use to make products faster, sturdier, and more attractive. The materials used by 3D printers will likely be proprietary. Whichever company can come up with the best materials will likely win. A 3D printing company may sell only one 3D printer to a company like Nike, but they will be providing the material that the printer needs to make those shoe cushions for many years to come.

3D printing is here to stay. It’s just going to take a bit longer for it’s full impact to be felt to individuals. Smart manufacturing companies should be trying to figure out how to incorporate this powerful technology right now.